Company founded

ROC (1989)

Managing Director

De-Yuan Wang王得源

Capital

NT$80,000,000

Number of Employees

200 people

Business Scope

- Design and manufacturing of plastic mold

- Manufacturing of varieties of plastic inject molding

- Assembling on varieties of semi-finished product

- Single piece part processing by CNC automatic lathes.

【Design, manufacturing processing and trading on varieties of components and mold.】

-

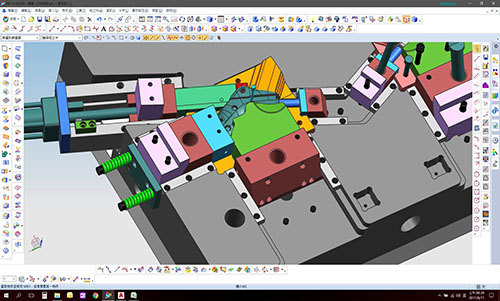

Design Department UG.Autocad. Moldex3DWith the development of high-tech industries and plastic industries, the customers are eager to obtain the excellent mold design.

With its professional mold technologies and computer software like AutoCad, Your Show assists the customers in developing the design of new product, appearance and structure, etc.

From the product design, mold design and mold manufacturing to the injection, it forms a consistent service system, which reduces the schedule for customer developing their new products to satisfy the needs at the client-end.

Software for Mold Design:

Software for Mold Design:- Siemens NX 11 (original named as UG)

Improves the efficiency of mold design, speeds up the process of 3d mold design and reduces the error during mold production. - AutoCad 2017

Make use of drawing environment in establishing the annotation for suitable size of measurement, it improves the work efficiency of engineering drawing with comprehensive editing and annotation in the production of 2D document and shortening of time in drawing issuance. - Moldex3D R14.0 (CAE)

Based on the most advanced true technologies of 3D simulation analysis, it simulates the process for injection molding and computerizes the result, which could assist the problem solving during the design and manufacturing of varieties of plastic products, verify and optimize the product design and mold design to reduce the number of mold testing and shortening of schedule on product launching.

- Siemens NX 11 (original named as UG)

-

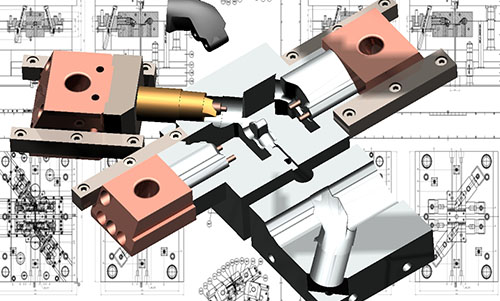

Mold making DepartmentThe mold manufactured by Your Show Company makes use of the advance technologies and applies the all-dimensional machinery equipment of computer precise processing from the initial concept design to the completion of end mold. The self-processing and manufacturing inside the plant and automatic measurement by 3D SCAN computer aided could reduce the error caused during the mold assembling.

The mold decides the product quality, efficiency and capability of new product development. So, the mold also possesses the reputation called the mother of industry. -

Forming DepartmentYour Show Inject Molding Plant applies the prevision inject molding machine, which could elevate the injection level from the self-component to the large scaled exterior parts (850t Machinery) to meet the overall needs at the client-end. During the production process, it invested in the automatic equipment so that the quality could be more stable besides the accumulation of experience on its mold design and inject molding. The good quality relies on Mold Department, Design Department, QM Department. Each department in production management supervises and cooperates with each other to achieve the stability of quality to win the trust and confirmation at the client-end.

-

Quality Assurance DepartmentYour Show is professional in its mold manufacturing, processing technologies on plastic molding. The enterprise’s competitiveness strength not only roots from its quality but also depend on the inspection procedures prepared by the customers, which could be quantified so that the customer could be relieved on the quality of product.

Besides its sprites on the internal process is in compliance with PDCA circulation and continuous improvement, it implements the quantified verification and action on self-inspection at the site, investment on several items of inspection equipment and application of automatic measurement to ensure Your Show’s quality commitment to the customers. -

Processing EquipmentYour Show adheres to its 30 years’ professionalism and concept on mold manufacturing and inject molding. It persists in the strictest attitude on product from the single piece of spare part to the single piece of part assembling and completion for ex-factory on the designing, mold opening and scaled production. They are produced by the automatic machines consistently in the standard plant to break through the traditional production mode, take the improvement on the efficiency of quality and manufacturing as a pre-condition and further develop the contract manufacturing business for each customer. Until today, it prepared a set of structure with clear division of work, processing procedure for checking at all levels to create excellent competitive strength for the customers. Right now, Your Show possesses dozens kinds of processing production equipment, which is divided into 6 big processing categories to provide the customers with the most excellent processing environment for producing the parts of more stable quality.

-

Vision※ Excellent Quality

Vision※ Excellent Quality

※ Dedicated Services

※ Technological Inheritance

※ Sustainable Operations